The gantry robot has the advantages of a large payload range and high efficiency, with a load capacity ranging from 0.1 kilograms to 3 tons. The number of controlled axes can vary from two to twelve according to process requirements. Juneng Robotics come with corresponding standardized platforms, meeting the automation needs of the vast majority of component manufacturing.

In response to the automation logistics demands of digitalized workshops, the company has developed various forms of logistics, including material channels, storage bins, servo stackers, etc. These solutions are equipped with functions such as material storage, loading, unloading, sorting, stacking, etc.

Utilizing 3D vision technology, we precisely locate disordered raw materials and transmit the coordinates to the robot, enabling seamless and efficient disorderly grasping. Juneng Robotics takes pride in its autonomous development of advanced 2D and 3D vision grasping technology, known for its swift computation speed and robust resistance to light interference.

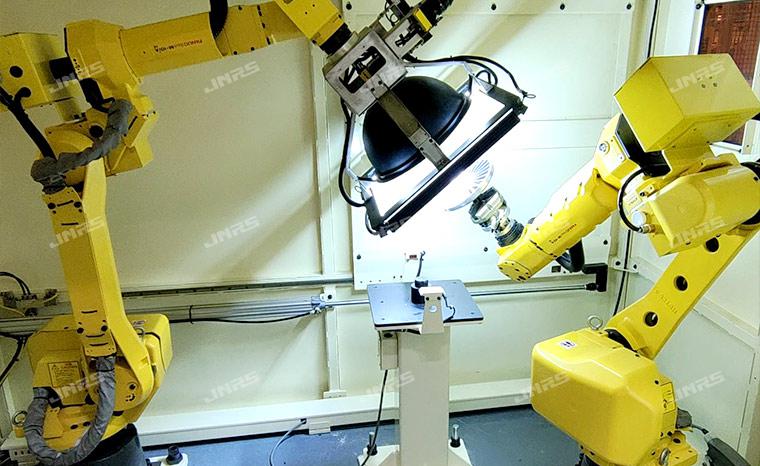

Defect detection technology is employed to identify non-compliant components on the production line with precision and efficiency. It adeptly recognizes various flaws, including sand-holes, dents, scratches, and more. Collaborating seamlessly with robots to create a dedicated inspection workstation, this technology effectively frees personnel from the complexities of manual inspection tasks.

Utilizing robot technologies like high-pressure flushing, reverse flushing, and vacuum drying, we automate the cleaning process on the production line. This includes efficiently removing iron filings and oil stains from simple components to achieving meticulous cleaning of diverse high-standard and intricate cavities.

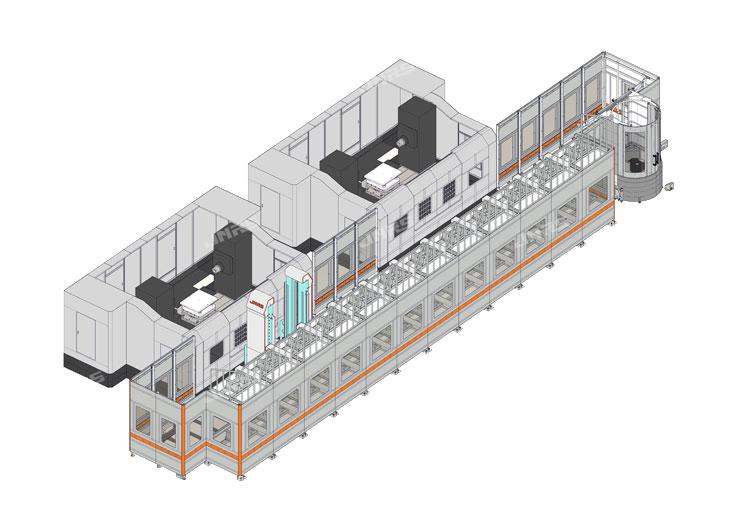

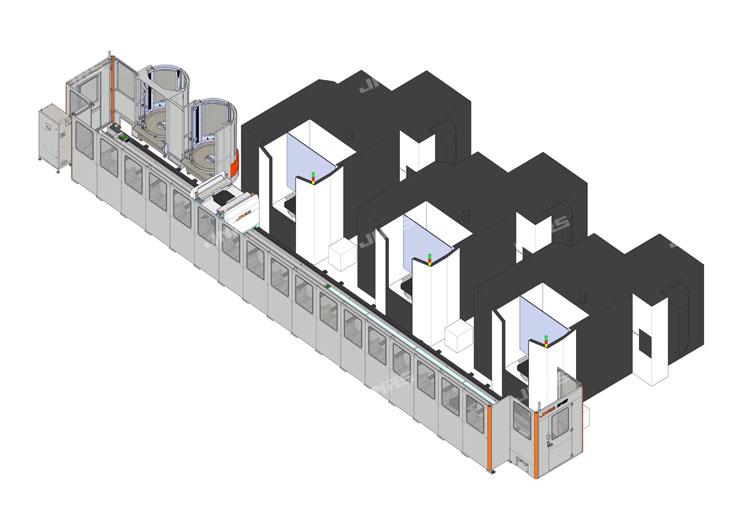

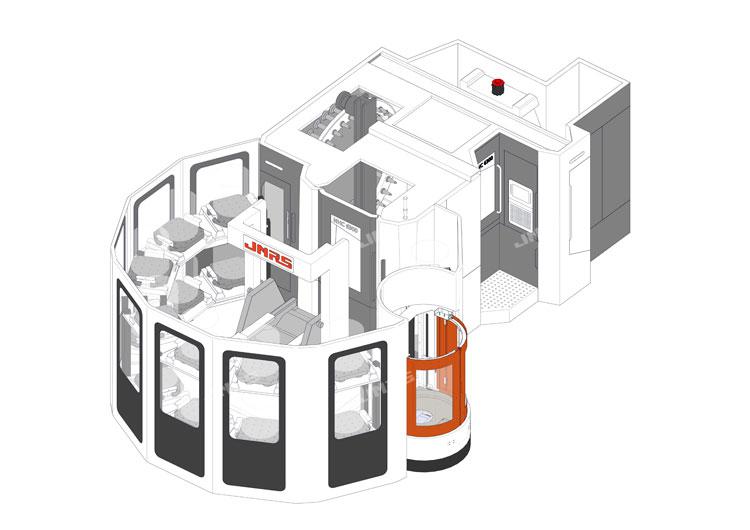

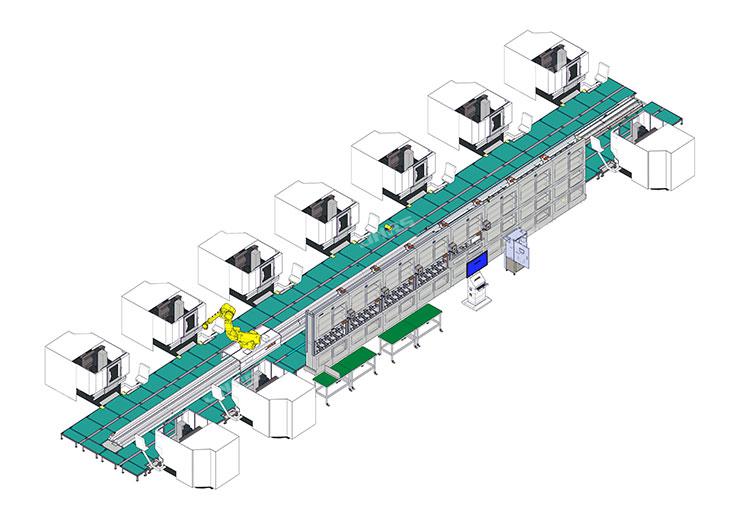

The FP series is a transport system based on RGV for handling machine tool pallets or zero-point fixture pallets. It represents a product tailored for flexible machining using advanced manufacturing software. The product line includes FLP, a flexible linear pallets system, and FCP, a flexible circular pallets system. This system ensures compatibility with diverse components, enabling efficient production changeovers through the replacement of machine tool pallets. The system encompasses processing machine tools, RGV cart handling system, line-side storage, loading and unloading stations, as well as cleaning units.

The FP series is a transport system based on RGV for handling machine tool pallets or zero-point fixture pallets. It represents a product tailored for flexible machining using advanced manufacturing software. The product line includes FLP, a flexible linear pallets system, and FCP, a flexible circular pallets system. This system ensures compatibility with diverse components, enabling efficient production changeovers through the replacement of machine tool pallets. The system encompasses processing machine tools, RGV cart handling system, line-side storage, loading and unloading stations, as well as cleaning units.

The FP series is a transport system based on RGV for handling machine tool pallets or zero-point fixture pallets. It represents a product tailored for flexible machining using advanced manufacturing software. The product line includes FLP, a flexible linear pallets system, and FCP, a flexible circular pallets system. This system ensures compatibility with diverse components, enabling efficient production changeovers through the replacement of machine tool pallets. The system encompasses processing machine tools, RGV cart handling system, line-side storage, loading and unloading stations, as well as cleaning units.

The FR series is a transport system based on Robots for handling machine tool pallets or zero-point fixture pallets. It is designed as a product for flexible machining using advanced manufacturing software. This system ensures compatibility with various components, allowing for efficient production changeovers achieved by replacing machine tool fixture pallets through the zero-point positioning system. Components of the system include processing machine tools, a robot pallet handling system, line-side storage, loading and unloading stations, as well as cleaning units.

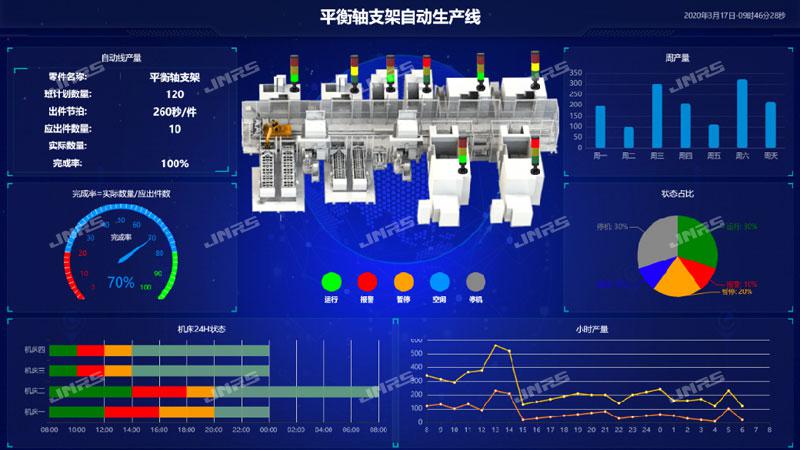

Building upon a deep understanding of the prevailing data acquisition technologies in mainstream CNC machine tool control systems, Juneng Robotics has innovated the lightweight J-MES system designed for intelligent factories. This system seamlessly integrates data collection, real-time monitoring, and comprehensive management functions for planning and intelligent scheduling. Noteworthy for its low coupling and easy scalability, the system empowers users to finely, precisely, and efficiently manage and control production resources, equipment, personnel, and processes.

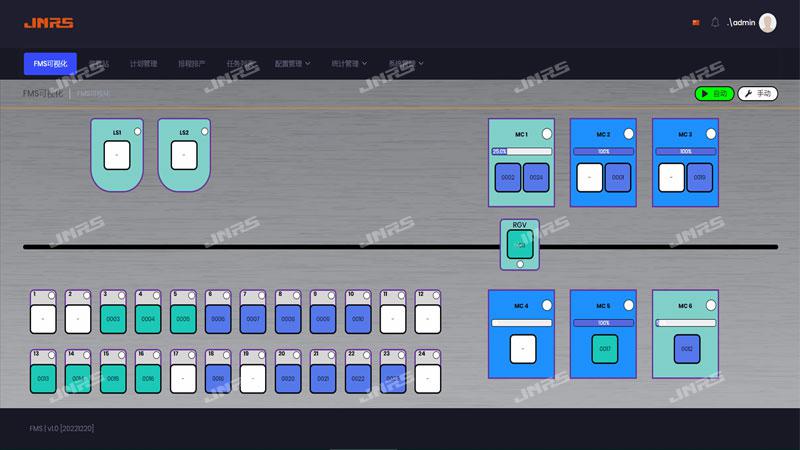

Juneng Robotics' R-FMS Flexible Manufacturing System is designed to facilitate simultaneous mixed-line production of various components on a single automated line. It seamlessly integrates with the user's MES system, allowing for the direct planning and management of production orders within the system. This system excels in flexible scheduling and intelligent production planning for multi-machine and multi-variety production scenarios. Furthermore, it enables remote monitoring of production status, issuance of production plans, and adjustment of production sequences through smart terminal devices like smartphones. This results in a highly intelligent and adaptable production model.

By harnessing cutting-edge IoT technology, Juneng Robotics has independently developed an intelligent remote proactive service platform. Through IoT connectivity, the automated production lines incorporating Juneng Robotics' equipment are seamlessly linked to this proactive service platform. The platform can promptly capture alarm signals from the production line's lights, ensuring users receive timely after-sales service. Furthermore, leveraging historical big data from production line operations, it identifies potential fault-prone areas and times, proactively alerting users to undertake preventive maintenance. This proactive approach minimizes downtime for maintenance, and the gathered data serves as valuable insights for Juneng Robotics in guiding product and technology improvements, driving a continuous cycle of upgrades.

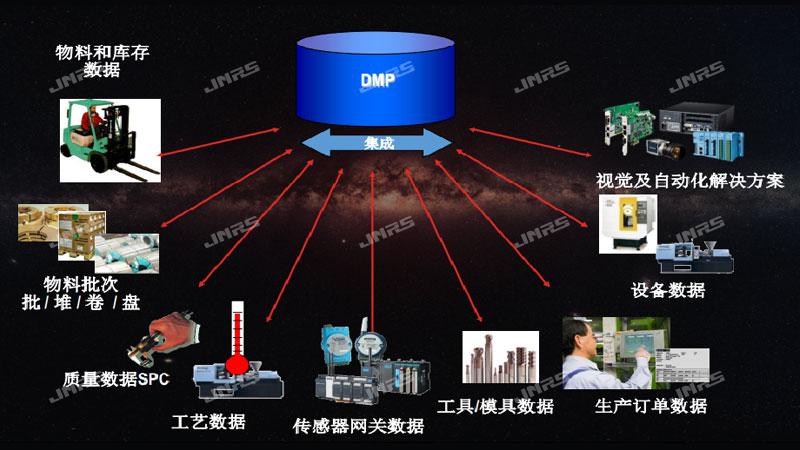

Juneng Robotics has developed an independently patented data management platform. This platform is capable of efficiently collecting data from different CNC equipment and diverse interface protocols. It creates a unified and standardized dataset for upper-level systems, enhancing the efficiency and concurrency of data collection. The platform supports a variety of heterogeneous systems, enabling effective management of drive assemblies and ensuring high efficiency, concurrency, and scalability.